Having licensed Magmasoft two years ago, Spokane now has recorded some significant changes in its casting process. They’re also able to resolve them faster than any competitor not using simulation technology. Thus, foundry engineers discover a casting’s potential problems before an order arrives at the melt deck.

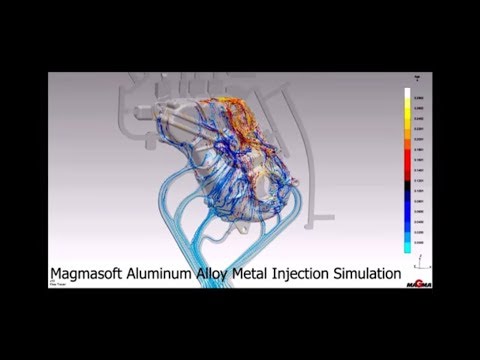

#MAGMASOFT SIMULATION SOFTWARE#

Using the software to run detailed process optimization for the casting process means that Spokane can identify process issues anywhere in the production sequence before the first run. By the time we are ready to run the part, we have confidence we will have a quality part on the first run, in most cases.” “We now catch problems before they become problems. “This is a very powerful tool, giving us the ability to see virtually the entire casting process before we have invested significant time and materials,” added Tyrus Tenold, president of the foundry division. “Having Magmasoft has improved our ability to reduce the number of samples and bring quality products to market faster through meeting specifications, tolerance, and metallurgy, most often on the first run,” CFO Ken Vorhees reported. By adopting Magmasoft (Spokane quickly discovered how the software’s ability to simulate the casting process from start to finish not only was invaluable as an engineering tool, but one that enhanced the entire business. Decades of growth have established Spokane Industries as an environmentally sound and technologically advanced organization, working with customers using technological resources that include Magmasoft ® process optimization software. Today, the foundry’s products include durable wear parts for impact crushers, and a variety of high-specification castings for construction, mining, manufacturing, transportation, aluminum, and defense manufacturing. Some of its current customers were among the foundry’s original accounts, even ordering castings from their original patterns. The Spokane Steel Foundry division is the core operation of Spokane Industries, having supplied commercial and industrial customers around the world for over 50 years. Those customers rely on Spokane for more than castings: they count on the company to address their own design and production problems. of production space in Spokane, WA, and its customers span a range of manufacturing interests: aerospace, construction and agriculture, transportation, aggregate processing, and general manufacturing.

Spokane Industries is a company that includes a steel foundry, a ferrous investment casting foundry, and a metal fabricating business.

0 kommentar(er)

0 kommentar(er)